Contact Us

Businesses can stay ahead of the curve and thrive in today’s digital age with us. Find out how we can help you.

Contact UsFUJIFILM Business Innovation's multifunction printer (MFP), the "Apeos C7070", was honored with the prestigious "BLI Pick Award*" by Keypoint Intelligence, a recognized authority in business printer evaluations. Among the criteria for this accolade, our MFP’s image quality was highly evaluated. This recognition is a testament to decades of technical research and our unrelenting commitment to meeting customer needs. In this interview, we spoke with two engineers working at the forefront of image quality development to uncover their passion and dedication.

* The Buyers Lab Pick Award by Keypoint Intelligence recognizes top-performing products through rigorous testing in areas like durability, usability, and image quality, serving as a reliable benchmark for excellence.

We often use the "copy" function on an MFP without a second thought, but if you break it down, it involves three key processes: "scanning," "image conversion," and "printing." Behind this seemingly simple workflow lies a wealth of advanced technology aimed at reproducing documents as faithfully as possible while delivering image quality that captivates the human eye. Today, we sat down with Namiki and Sugimoto, two engineers dedicated to image quality design, to discuss their unwavering passion for excellence.

From left to right: Namiki and Sugimoto

Tatsuya Namiki: Image Quality DesignerHe has been involved in image processing design for copying and scanning functions in MFP since joining FUJIFILM Business Innovation Corp. in 2010.

Shuichi Sugimoto: Image Quality DesignerHe has specialized in image quality technology for the printing function of MFP since joining FUJIFILM Business Innovation Corp. in 2010 and has also contributed to the development of image adjustment features.

Namiki: Our starting point is always to reproduce the original document as faithfully as possible. During the process of converting colors from RGB (additive primary colors: red, green, and blue) to CMYK (subtractive primary colors: cyan, magenta, yellow, and black), it is designed to ensure minimal color differences. Achieving this level of fidelity requires a variety of intricate image processing techniques. These include:

Area Separation Techniques: Identifies text and graphics within a document.

Image Filtering: Enhances the edges of text to make characters crisp, while optimizing the sharpness and smoothness of graphics.

Tone Correction: Prevents tonal gradation issues and ensures accurate color reproduction.

These precise technologies enable sharp text and smooth graphics to faithfully reproduce.

However, fidelity alone is not enough to fully satisfy our customers. When we copy a newspaper, its background color might impact the readability of the text. In such cases, background areas can be deliberately lightened, prioritizing text legibility. "Striking the right balance between faithful reproduction and necessary adjustments is a strength we’ve honed over 60 years of technical development.

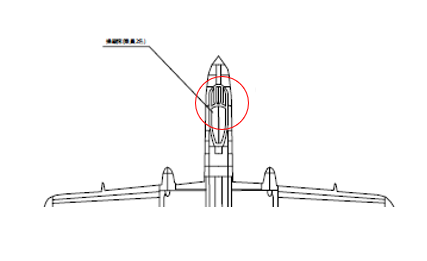

Sugimoto: The printing process involves five steps in xerography: charging, exposure, development, transfer, and fusing. Maximizing the performance of the components used in each stage is essential to achieving superior image quality. One example is fine lines or nuanced expressions of skin tones and landscapes—these often require adjustments that cannot simply be compensated for during image conversion.

Each process in printing is handled by different components, including drums, developers, transfer belts, and fusers, which require detailed parameter settings to achieve optimal output. For instance, in the developer, the exact amount of toner applied must be finely tuned. At the same time, we also must maintain balance across all processes, ensuring that adjustments in one area do not negatively affect others.

Sugimoto outlines two major considerations in parameter adjustment:

1.

Inter-process balance: For example, to improve the reproduction of fine lines, adding more toner during the development process might result in higher used toner waste during the transfer process, reducing overall efficiency. We must carefully manage trade-offs across process accuracy, toner consumption, component durability, and energy efficiency. With these trade-offs, we are able to provide customers with a machine that produces excellent image quality while being cost-effective and durable.

2.

Tolerance for Variations among Machines: Even slight manufacturing differences on ten microns scale can significantly influence image quality. In mass production, variability is unavoidable, however, we address this challenge by designing with a focus on capturing the 'median' of these variations. By identifying and understanding the median during the prototyping phase, we are able to optimize parameter settings. In addition, we continuously monitor image quality during mass production to ensure that any shifts are promptly addressed, further minimizing the effect of variability and maintaining consistent output quality.

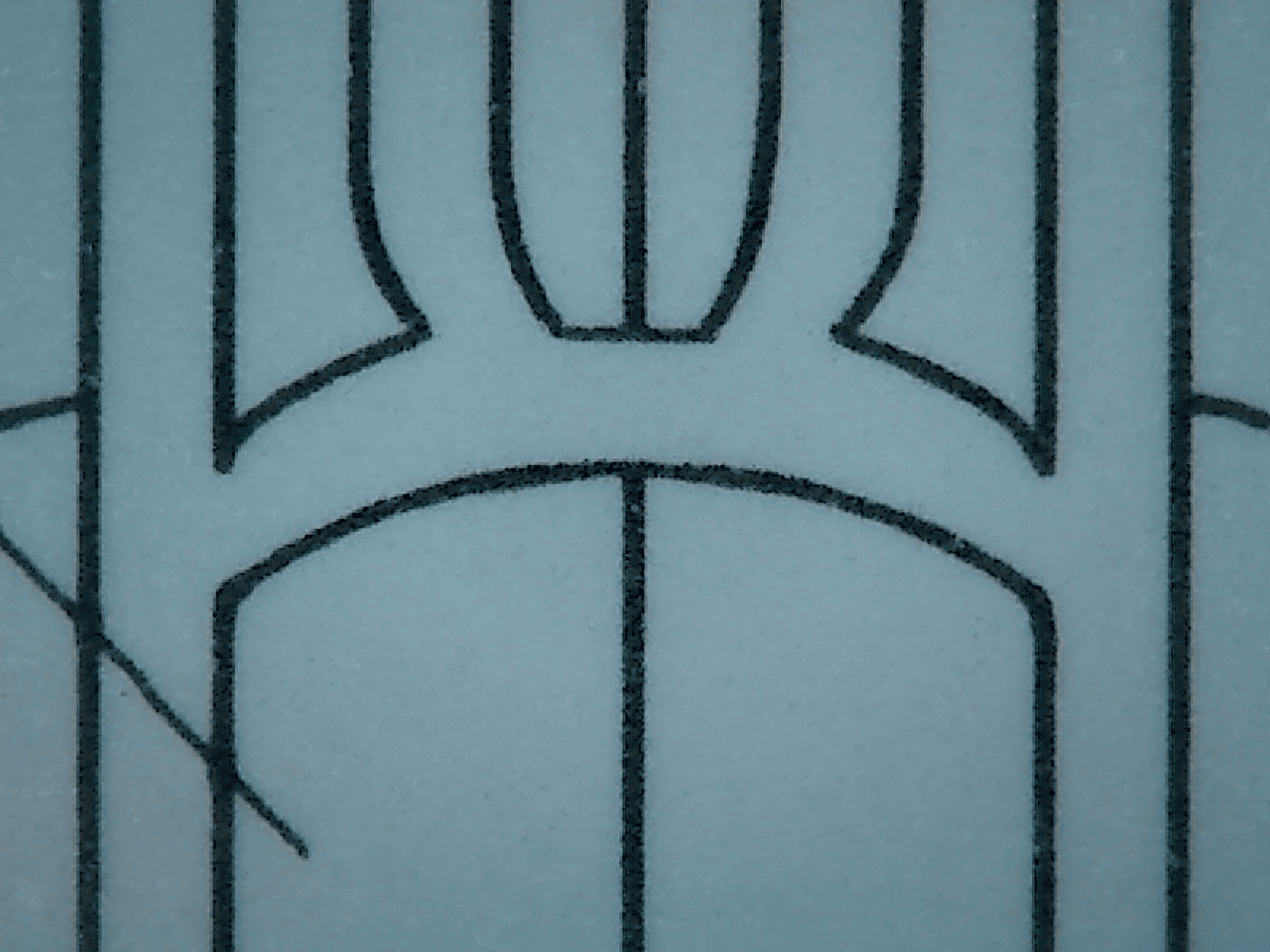

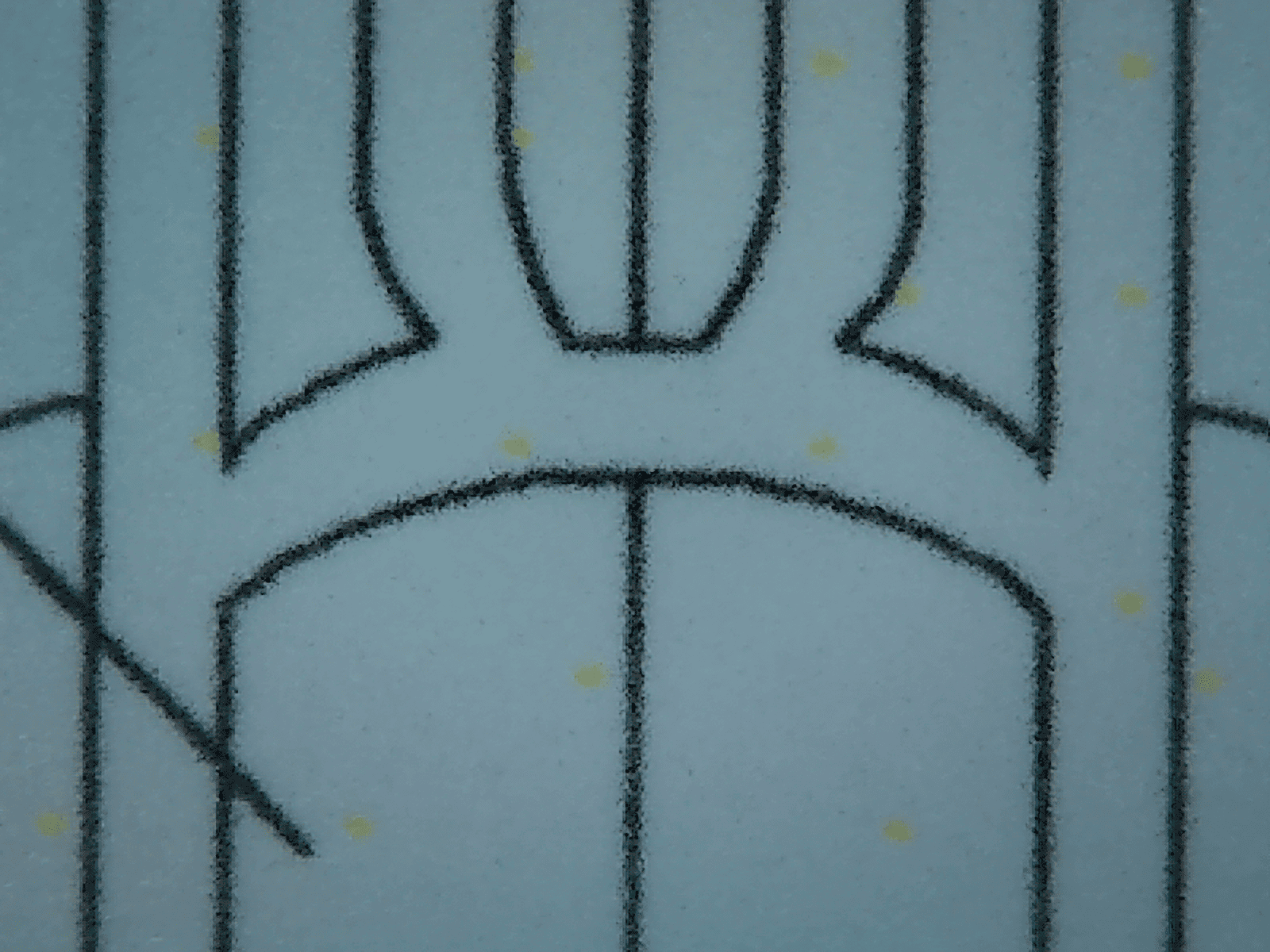

As a result of this meticulous effort, our MFP can achieve incredible precision in reproducing fine lines and nuanced textures.

Sugimoto proudly notes “We’ve succeeded in faithfully rendering even 1-dot and 2-dot lines with optimal sharpness, width, and consistency. This level of detail is something our competitors can’t match—it’s our distinctive strength.”

Original data (0.12 pt)

Print output

0.12 pt |

0.24 pt |

|

FUJIFILM |

|

|

Brand A |

|

|

Brand B |

|

|

Diverse feedback from the market serves as a driving force behind continuous image quality improvements. Namiki recalls one example related to the use of recycled paper.

Namiki: As the use of recycled paper increased, issues emerged regarding its lower whiteness and the impurities present in the paper, resulting in the problem of background staining in the copies. To address this, the team leveraged valuable customer feedback, conducting a survey of paper characteristics in the market. This research led to the implementation of optimized image processing specifically for recycled paper, successfully reducing background soiling and ensuring satisfactory image quality.

The insights we gain from the voices of our customers are invaluable. It is our duty to listen, address their challenges, and deliver solutions that meet their practical needs.

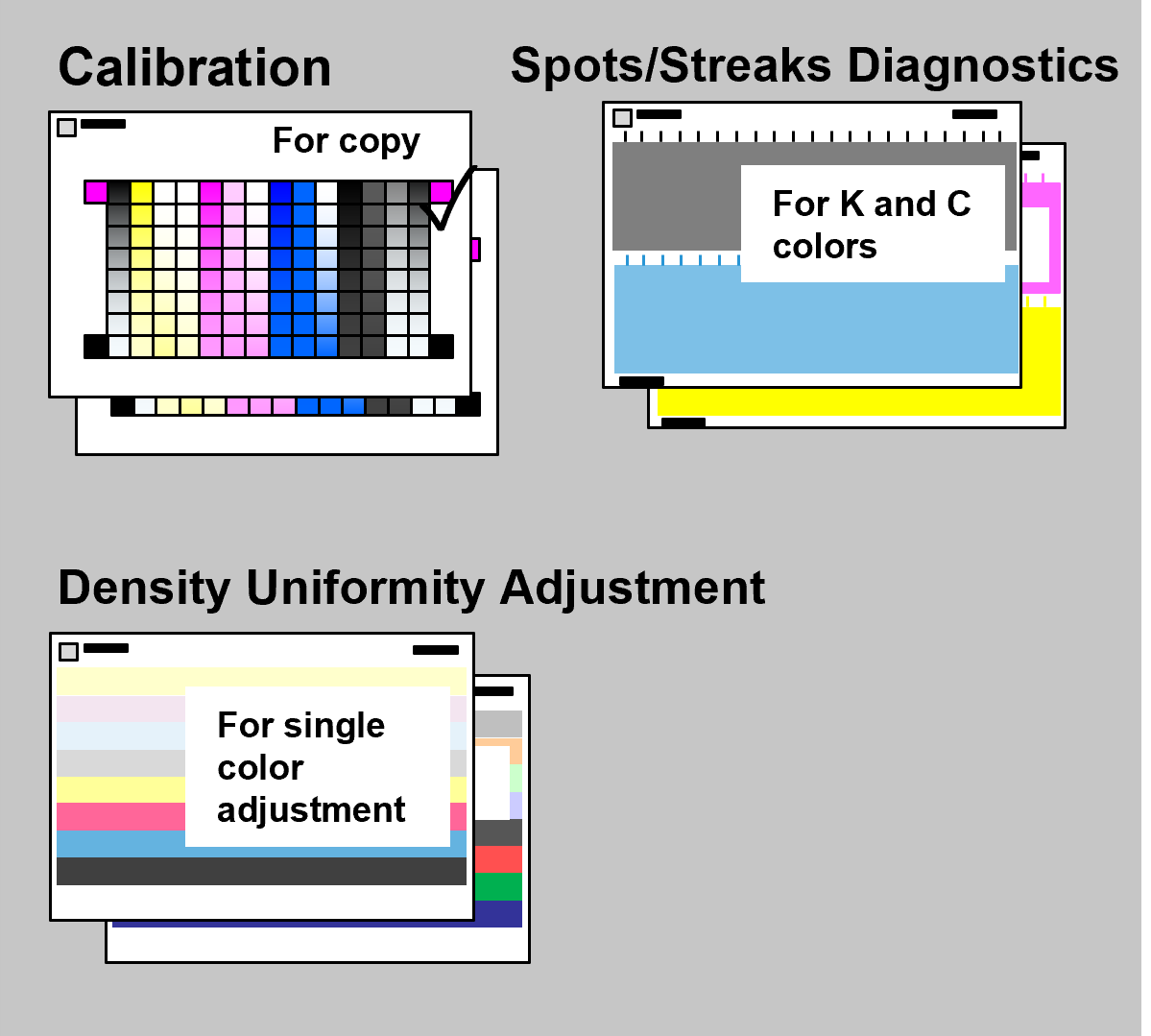

(1) Print out documents used for calibration.

(2) Scan calibration documents.

(3) Adjust image quality automatically.

The development of the user-friendly "Combined Calibration" (image quality adjustment) feature, an industry-first innovation, is a testament to the persistence and ingenuity of our engineers. This groundbreaking function empowers users to easily fine-tune image quality by themselves.

Sugimoto: In the past, customers were often left waiting for service engineers to visit and manually adjust the output quality. During this time, they were unable to enjoy satisfactory results, which sometimes disrupted their workflows and led to frustration. With Combined Calibration, all the user needs to do is print a dedicated test sheet and scan it back into the MFP. The machine then automatically completes the adjustment process, streamlining the task.

The underlying image processing technology had already been developed, but what truly set this innovation apart was our focus on the user experience. We asked ourselves, 'How can we make adjustments intuitive and effortless for customers who are not technical experts?' This perspective was crucial to the feature's success.

Through such innovations, we continue to deliver value in ways uniquely aligned with our philosophy of customer-centric technology.

Namiki: Customers take for granted that 'print quality should always be good,' but maintaining this standard is a critical challenge. This requires us to stay on top of trends like the rise in recycled paper usage while also considering cultural and market preferences. For instance, some countries or regions favor vivid color tones. By understanding what kind of image quality our customers truly desire and thinking deeply about it, we can provide the most suitable quality for every market and era. That’s the type of developer I aspire to be.

Sugimoto: While fidelity to the original document is key, we recognize that what’s visually 'accurate' may not always align with what customers perceive as the 'right' result. For example, even if we have the technology to print fine lines with absolute precision, a customer might prefer an output with bolder and darker lines for better visibility.

Our role is to make it possible for customers to shape their ideal outcome. By offering image quality functions that are both highly customizable and wide-ranging, we can deliver results that align closely with individual needs. Our ultimate goal is to go beyond satisfaction and create moments of delight—when customers see the output and think, “This is exactly what I wanted.” That’s the kind of value we strive to deliver and the challenge we will continue to pursue.

Namiki and Sugimoto’s shared commitment to understanding customer needs and translating them into innovative solutions is at the heart of our approach to image quality technology. By thinking beyond technical fidelity and focusing on the customer’s perspective, FUJIFILM Business Innovation ensures that its MFP offer not just functionality but also an elevated experience tailored to each individual user.

Businesses can stay ahead of the curve and thrive in today’s digital age with us. Find out how we can help you.

Contact Us