Contact Us

Businesses can stay ahead of the curve and thrive in today’s digital age with us. Find out how we can help you.

Contact UsFUJIFILM Business Innovation has proudly held the No. 1 market share* across Asia Pacific region, earning trust through advanced printing technologies that continuously meet evolving customer needs. This excellence results from decades of accumulated experience by dedicated developers.

In this interview, we reveal the unyielding passion and technical mastery of the marking unit development team responsible for image formation during printing.

* IDC data Source: IDC WW HCP Tracker, 2025Q3, Share by Company A3 Color Laser Shipping units, Year: CY2024

Target market: Whole AP

From the left: Mitamura and Miyata

Naoya Mitamura: Transfer Function DesignerHe has been deeply involved in transfer process development for multifunction printers (MFPs) since 2014.

Toshiyuki Miyata: Fusing Function DesignerHe has extensive experience in developing fusing processes and has also contributed to transfer technology development since 2004.

Mitamura: My focus has been on ensuring image quality through transfer technology. ‘Transfer’ is the process of moving developed toner images from the photoconductor drum onto paper via the transfer belt. This step directly impacts image resolution and sharpness. If transfer is inadequate, toner does not fully transfer to paper, resulting in faint or broken images. Additionally, ‘transfer belt cleaning’ after this step is critical. Removing leftover toner prevents contamination in subsequent prints, ensuring output matches the original. Thus, successful transfer technology depends on both accurate toner transfer and effective toner removal from the belt. To perfect this, we conduct thorough lab tests under various conditions to ensure the best performance across different environments.

Miyata: I have worked with Mr. Mitamura on transfer technology, and also specialize in the fusing process, which follows transfer. Fusing uses heat and pressure from the fuser to melt toner and permanently bond it to paper. We must pursue how to best fix toner onto paper to ensure printed materials are durable. This step is crucial in determining the final print quality.

Mitamura: Since joining the company, I’ve committed to delivering stable transfer technology. I’m proud that the Apeos C7070 series, for which I was recently responsible, offers the highest transfer quality among all FUJIFILM Business Innovation devices to date. While building on existing technology, this was achieved by overcoming many challenges. Previous model devices I worked on had issues with toner cleaning—cleanup parts didn’t function as designed, leaving toner residue on the transfer belt. This caused repeated print defects and customer complaints. To understand the problem, we visited customer sites, observed environments, and gathered feedback. We found that the cleaning technology had not been fully optimized new toner materials, leading to swift corrective actions and changes implemented in later models.

For the Apeos C7070 series, we took a bold step by changing the materials used for key parts. The prior approach maintained quality but didn’t address expanding costs and diverse usage environments. This redesign was challenging and required coordination across departments, but successful collaboration resulted in unprecedented transfer technology. Compared to before, durability improved about threefold and customer calls decreased by approximately 75%. This direct on-site verification and radical improvement were proud milestones for me.

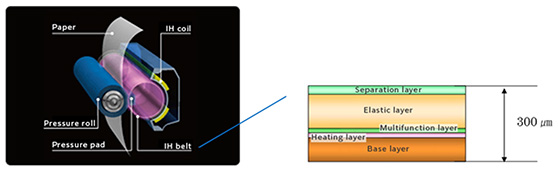

Miyata: The most memorable experience for me is developing the IH fuser, essential for the fusing process. As mentioned, fusing requires heat and pressure to melt toner into paper. Conventional MFPs took time to warm up, so they preheated the fuser continuously to prevent user wait times. This increased power consumption—even when idle, the fuser used energy to stay heated—accounting for about 80% of total device power usage at a maximum.

We asked: can we design a fuser that heats up quickly when needed, yet saves energy otherwise?

This led to a technology overhaul focusing on the IH belt inside the fuser. We considered utilizing copper in the heating layer of the IH belt. Up until then, copper was thought unsuitable for induction heating, but we found that it can be heated dramatically rapidly to the same extent as magnetic metals by thinning. Utilizing this, we developed an IH belt with ultra-thin (3 micrometer) copper layers—one of the thinnest in the world—enabling rapid heating.

As rapid heating risks overshooting target temperatures, we also developed control features to maintain precise set temperatures. These innovations allowed us to create an IH fuser that lowers power consumption without compromising user convenience. This breakthrough remains my proudest achievement.

Mitamura: One of the most important aspects of technology development and improvement is 'truly understanding how customers actually use MFPs in the field'. Sometimes their usage environments exceed our expectations. Most people imagine MFPs being used indoors in offices. However, I found the customer using an A3 MFP inside a temporary construction site office when I responded to a request to improve image quality. It was summer, and the paper absorbed moisture due to high humidity. Seeing this environment firsthand was eye-opening and made me realize the necessity of thoroughly adapting our products to varying temperature and humidity conditions. This direct customer engagement led to meaningful improvements beyond what we had assumed within the development team.

Miyata: In addition to customer visits, I also visit production sites and communicate closely with manufacturing teams. We share challenges and improvement ideas related to parts and discuss how to maintain stability in the marketplace. Currently, we’re focusing on recycling parts used in the IH fuser. By reviewing collected parts together, we explore efficient methods to recycle with consistent quality. The unique insights and experiences of production members are invaluable in driving effective recycling solutions.

Mitamura: What sets us apart in development is our commitment to deeply engage with real-world challenges. We pride ourselves on developers personally visiting sites and listening to customers and related departments — a level of responsiveness that surpasses our competitors. This approach enables us to design better technology that is not only more durable but also reliably delivers the output quality customers expect throughout the parts’ lifecycle.

Mitamura: I believe it is essential to avoid any major gap between what customers expect and the output quality we deliver. By actively listening to our diverse customers and striving to reduce technical challenges to near zero, we are confident our technological excellence will translate into real value. Moving forward, we plan to shift towards developing MFPs that provide new added value, contributing even greater technical benefits to our customers.

Miyata: Customer values are rapidly evolving, especially with environmental consciousnesses becoming a key added value. We feel a growing responsibility to enhance energy-saving capabilities beyond current standards. While maintaining the hallmark image quality and device reliability that we have delivered for years, I aspire to be an engineer who also creates new value areas for our customers going forward.

Businesses can stay ahead of the curve and thrive in today’s digital age with us. Find out how we can help you.

Contact Us