- Realize top speed for both uncoated paper (52-400 gsm) and coated paper (72-400 gsm).

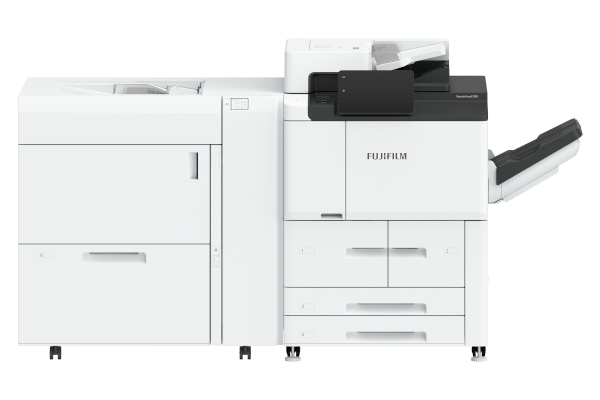

- High-productivity A3 printing at 55 ppm.

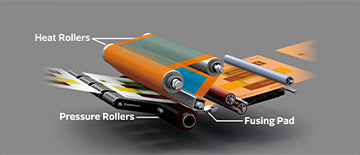

- The compact belt-roll fuser that enables efficient heating achieves high productivity and high image quality on wide variety of paper stocks including heavyweight.

G7 calibration achieves consistent gray balance and neutral tonality across different printing processes, substrates, and printing conditions. A standard that is widely adopted in the printing industry to ensure colour consistency and quality across various printing technologies and platforms.

- Note: G7® is Idealliance’s global industry-leading set of specifications for achieving visual similarity across all print processes.

- *1 G7 certified the combination with Revoria Flow Print Servers.

- 1,200 x 1,200 dpi RIP processing reproduces images with their original vivid quality. Even fine text and lines can be reproduced at 1,200 dpi resolution.

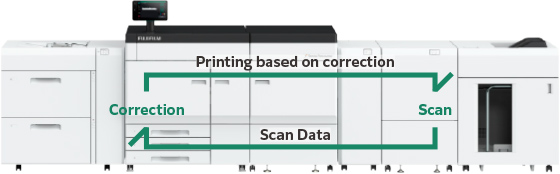

- High-precision 3D calibration and feedback functions ensure consistent colour reproduction.

- Different-sized data can be imposed at any desired position for more efficient use of banner sheets and reduced paper waste.

- Automatic detection and correction of colour density variations and front-to-back misalignments during printing.

- Optimization continues throughout the printing process, with little to no decrease in print speed.

- *2 Smart Monitoring Gate D1

- AI automatically identifies the scene per photo, applies appropriate image correction, and prints them beautifully.

- skin tone

- brightness

- texture

- brightness

- sky colour

- noise

- backlight

- sharpness

- Printed material is compared with the RIP image during printing to detect anomalies.

- This streamlines the laborious task of checking for print irregularities, saving significant time and effort.

- Image inspection:

- Detects dots, dirt, print defects, and paper folds.

- Barcode/OCR:

- Checks readability of characters and barcodes, numbering information continuity, and front/back characters and numbering continuity.

- *3 Optional

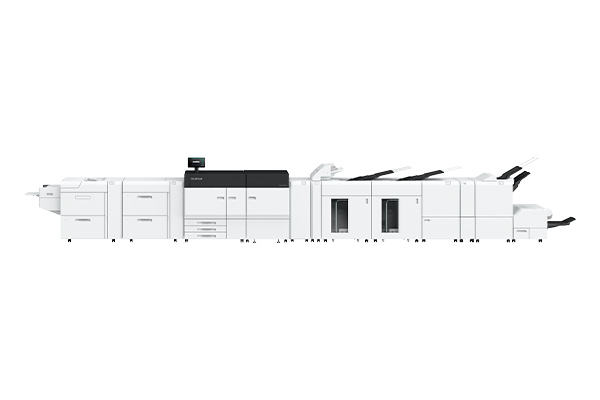

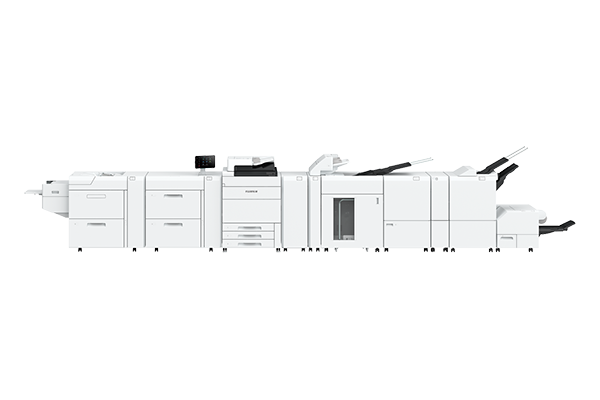

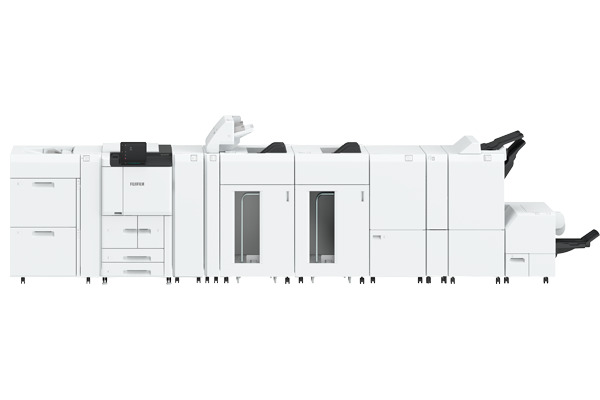

- Offer better solutions thanks to reliable technologies that enable a wide variety of paper sizes and post-processing.

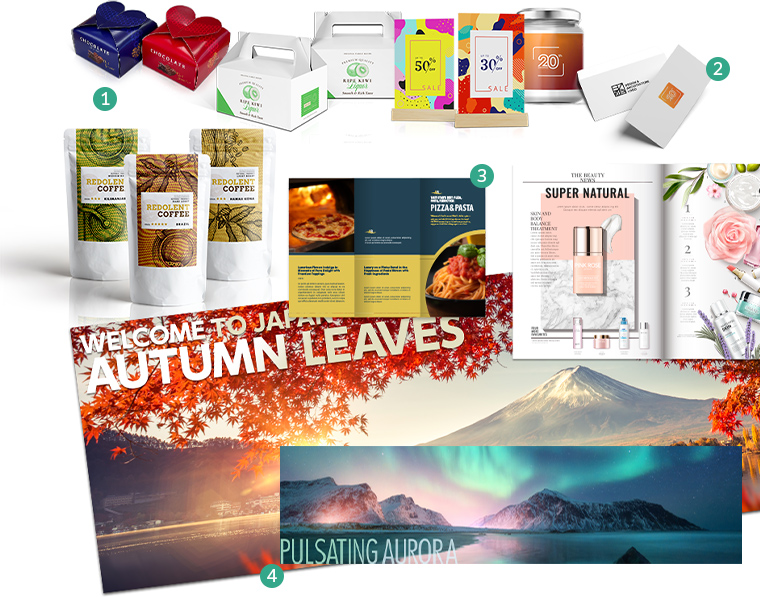

- Supports a wide range of paper sizes, from a minimum of 90 x 146 mm up to 330 x 660 mm, with optional banner sheet printing (single-sided) up to 330 x 1,300 mm.

- Paper weights flexibility from lightweight 52 gsm to heavyweight 400 gsm.

- Folding carton and label sticker

- Printing on envelopes with a minimum paper width of 90 mm

- Printing on water-resistant paper for menu lists

- Supports banner sheet sizes up to 330 x 1,300 mm.

The intermediate transfer belt ensures reliable, high-quality output even on typically difficult-to-print textured media, such as embossed papers.

- Enables stable paper handling.

- Protect operators safely from high amount of static electricity.

The air-suction feed tray, equipped with our proprietary Shuttle Head technology, ensures a reliable feed of papers prone to paper dust accumulation, textured papers, and coated papers that tend to stick together.

- *4 Static Eliminator D1

- *5 Air Suction Feeder

Revoria XMF PressReady is an intuitive centralized management software that empowers Print Service Providers to manage job submission from multiple sources (Web-To-Print System, Print Management Information System, and PDF files from customers) efficiently.

With Revoria XMF PressReady, you can also automate repetitive tasks such as pre-flighting, imposition, grouping, sorting, numbering, etc. and direct specific print jobs to the appropriate digital press based on the prescribed condition set.

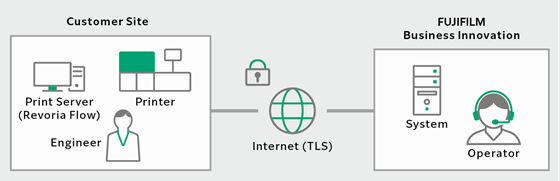

FUJIFILM Business Innovation Remote Services enhance machine reliability, uptime, and productivity, ensuring seamless business operations. Using remote services to connect our support systems and tools with skilled teams worldwide, we deliver responsive assistance precisely when you need it. This proactive approach, supported by in-depth knowledge and comprehensive product understanding, lets us offer the solutions you need.

- Seamless one-way communication between your device and our data centre.

- Reduce downtime by transmitting machine data to detect and prevent problems.

- Automatically report billing meters to save time and improve accuracy.

Automatic downloading of software patches for the print server, regular collection of operation logs, and transmission of error logs to the log server. These functions help prevent issues from occurring, facilitate faster repairs, and reduce downtime.

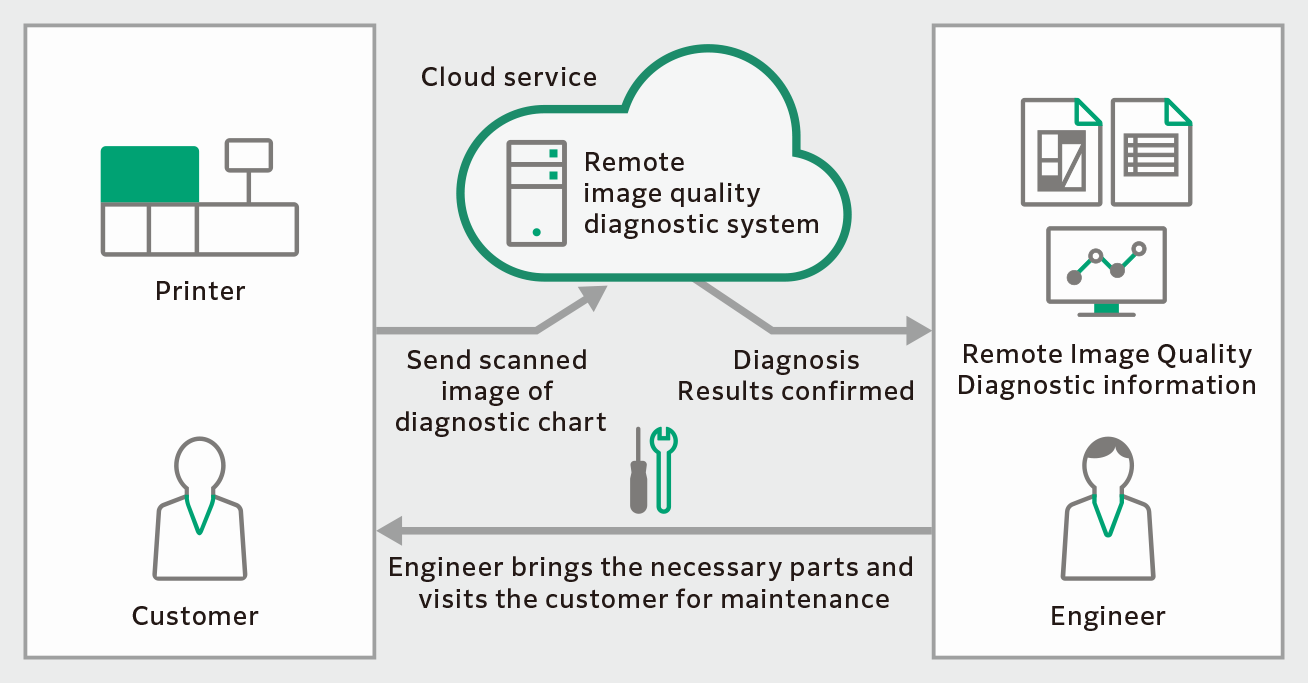

By diagnosing the output image quality of customer machines remotely, it contributes to stabilizing image quality.

- The necessary parts and the repair procedures can be prepared in advance, thus minimizing the machine downtime.

- The diagnostic result and maintenance history of each machine are remotely collected and accumulated, and these records are used for effective maintenance.

- *6 This support availavility varies depending on the location. For more information, please consult your assigned sales representative.