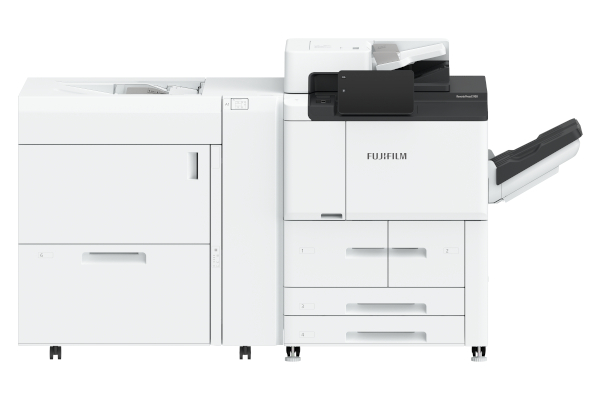

These options make it possible to build flexible printing systems suited to every printing operation.

Up to a total of 12,450 sheets can be loaded. You can enjoy long-time seamless operation at continuous mass printing with less paper refill frequency.

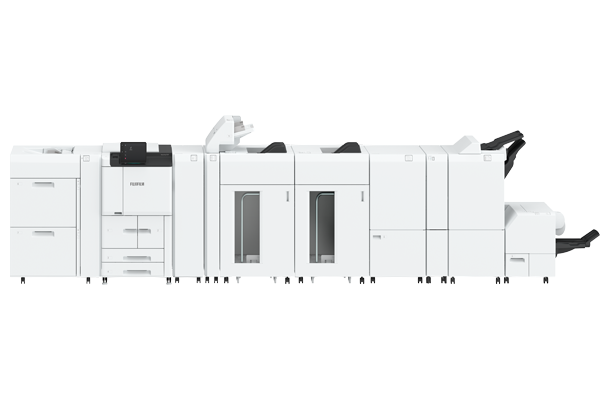

High Capacity Feeder C1-D2

- Maximum A4 x 2 trays

- 2,000 sheets x 2 trays

- Maximum A3, 330.2 x 488 mm

- 2,000 sheets x 2 trays Air assist

- Maximum A3, 330.2×488 mm

- 2,100 sheets x 2 trays + 250 sheets

- Air suction

- Maximum A3, 330.2 x 488 mm

- 2,000 sheets x 2 trays x 2 connection

- Air assist

- Maximum A3, 330.2 × 488 mm

- 2,100 sheets x 2 trays x 2 connection + 250 sheets

- Air suction

- Note: The photo shows Finisher D6 with Booklet Maker.Square Back Fold Trimmer D1 cannot be connected to Finisher D6.

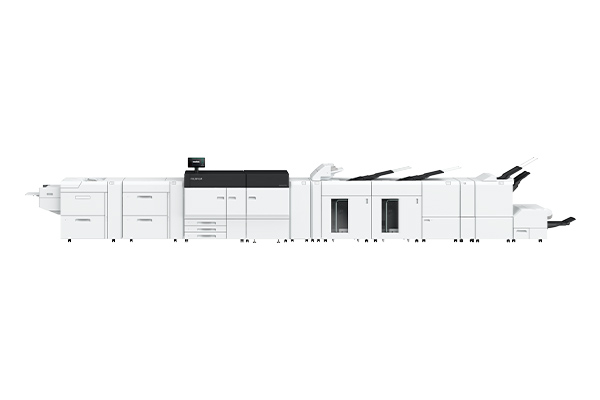

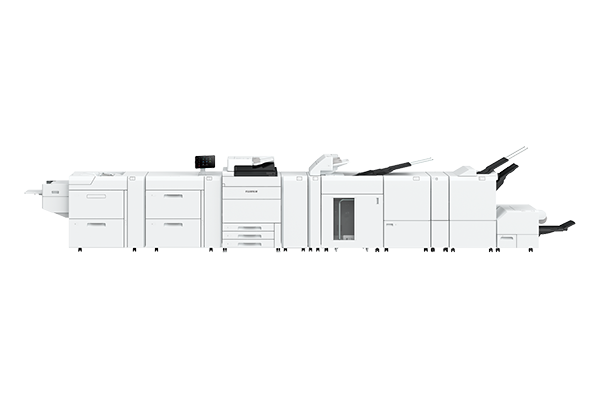

- Real-time paper curl correction

- Cover/sheet insertion

- Scanning print pages

- 5,000-sheet offset-stacking for mass printing

- Stacker cart

- Connection with 3rd party finisher

- 5,000-sheet offset-stacking for mass printing

- Stacker cart

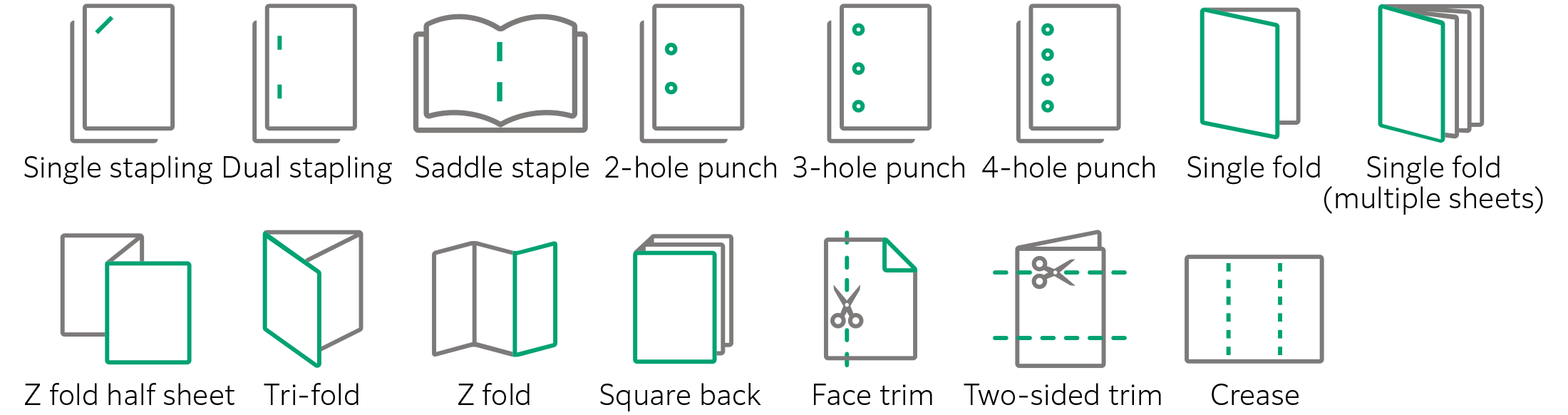

- Two-sided trim

- Crease

- Z fold half sheet/Tri-fold

- 100-sheet stapling with auto staple cutting

- Hole punch*1

- 100-sheet stapling with auto staple cutting

- Hole punch*1

- Saddle staple/Single fold

- Face trim

- Square back

- *1: Optional.

- *2: Available only with Finisher D6 with Booklet Maker.

High Capacity Stacker A1 can accommodate up to 5,000 sheets. The printed sheets are directly delivered to the stacker cart (carriage). It is useful when carrying large volumes of printouts to off-line post-processing devices.

High Capacity Stacker A1 is also available in dual combination.Using two Stackers alternately, it enables high productivity by continuously extracting printed materials without stopping the printing process.