Feedback and Inquiries

We would be most pleased if you would let us know any feedbacks or inquiries you might have about our sustainability initiatives.

Based on the concept that "used products are valuable resources, not waste," we established resource circulation system in 1995 that covers the entire product life cycle from the product planning/development/manufacturing stages to disposal.

Aiming for virtually "zero waste", parts taken from collected used products are reused through recycling technology and circulated as resources.

In 1995, FUJIFILM Business Innovation established the Recycling Policy to collect, reuse, and recycle used customer products, and in 1996, we became the first company in the industry to introduce products with reused parts to the market.

In 2000, we were the first in the Japanese industry to achieve virtually zero waste (recycling rate of at least 99.5%).

In 2008, we established a reuse/recycling site in Suzhou, China, expanding our activities overseas.

In addition, we have promoted the expansion of utilization of reused parts, and in 2010, we commercialized the remanufactured machines as products.

In May 2024, the FUJIFILM Group's CSR plan, Sustainable Value Plan 2030 (SVP2030), we set new targets for resource circulation.

Furthermore, we are contributing to the reduction of resource usage in our customers' printout environments by providing Managed Print Services (MPS).

In order to accelerate the promotion of resource circulation, which is a key issue in the Sustainable Value Plan 2030 (SVP2030), we have established a new target for our multifunction device business.

"Natural resource input ratio of 60% or less by 2030."

We will further strengthen our activities by expanding our existing activities to new markets.

We are working to reduce the size and weight of our multifunction devices and printers.

The Apeos C320 z, launched in April 2021, has achieved a 30% reduction in weight and a 40% reduction in volume compared to previous models by reducing the number of parts and reviewing the design layout. By reducing the weight of parts and materials used, we have also achieved a reduction in CO2 emissions.

Materials used in both past and current products are introduced here.

To reduce the use of petroleum-based plastics, we use flame-resistant biobased plastic parts made from "cellulose" obtained from wood materials.

To help solve the marine litter problem, which is having a serious impact on marine life and ecosystems, we took on the challenge of utilizing plastics made from marine plastic litter as raw materials for the main body components of our multifunction devices thereby promoting the collection of marine plastic litter.

In February 2024, we started to introduce plastic cover parts made of marine plastic and recycled plastic as raw materials for the main body of the remanufactured machine, the first initiative of its kind in the industry1.

We design our multifunction devices and other products based on our reuse/recycling guidelines in order to effectively reuse parts taken from collected used products.

Design for a long lifetime : Extending the lifetime of parts to make them reusable

Design for easy separation : Separating parts with a short service life from the reusable parts to reuse the reusable parts

Robust design : Minimizing damage to parts caused during use, collection and recycling operations

Easy-to-disassemble design : Designing products in a way that facilitates disassembly for dismantling and the segregation of materials

Use of reusable materials : Selecting reusable materials to enable material recycling

Standardizing designs : Standardizing designs to enable the reuse of parts in other models and successor models

Based on the concept that end-of-life products are valuable resources, not waste, we have established and implemented design guidelines and procurement policies for reuse and recycling since 1995.

We are strengthening cooperation with parts and material manufacturers, not only within the company but also upstream in the supply chain, by sharing expertise and jointly developing reuse and recycling technologies.

Specific examples of design for reuse and recycling (Introducing designs used in both past and current products)

End-of-life products are automatically classified as either for reuse or for recycling by the "Collection Judgment System" upon receipt of a cancellation/collection order registered in the core system.

Based on the collection instructions issued, eligible machines are sent to the production sites of the remanufactured machines, whereas the machines for recycling are sent to the recycling partner companies, then they proceed to the reuse/recycling process respectively.

End-of-life products that have been determined to be eligible for remanufacture by the "Collection Judgment System" and transported to a remanufacture center are disassembled, diagnosed component by component by the "usage history information system," and automatically determined whether they can be remanufactured or not.

Parts that have been recovered using our proprietary cleaning and blasting technologies are utilized and assembled, and then undergo the exact same adjustment and inspection processes as newly manufactured machines to ensure the same quality as newly manufactured products before being shipped.

Since the 1990s, we have been collecting and reusing consumables such as used toner cartridges and toner recovery bottles to help reduce the use of natural resources.

In 2017, we achieved the recycling of toner carriers1, which have an important function in the electrophotographic process, and use recycled toner carriers for some of the toner carriers required for the production of developer2.

In addition to toner carriers, we continue to take on the challenge of reusing many other functional materials.

Used products generated nationwide that are determined to be recyclable through the "Collection Judgment System" are delivered to recycling sites.

At the recycling sites, the products are disassembled and sorted by our recycling partners who possess the latest recycling technologies, and are ready to be reused as resources.

In 2000, we achieved a recycling rate1 of over 99.5% (zero waste to landfill) in Japan, and we have maintained zero waste to landfill ever since.

Used machines and consumables are recycled by our recycling partners throughout Japan.

Collaboration with recycling partners in each region not only enables us to utilize the latest recycling technologies, but also to reduce CO2 emissions by reducing transportation distances.

Our Managed Print Services, which provide customers with an optimal printing environment, reduce the number of output devices and the amount of paper used, thereby helping customers reduce their resource usage.

Super EA-Eco toner reduces toner consumption by improving transfer efficiency1 through the uniform particle shape and form distribution achieved by the EA manufacturing method (emulsion polymerization method).

Furthermore, by reducing the particle size, the thickness of the transferred toner is thinner than that of conventional EA toner, resulting in reduced toner consumption.

Furthermore, the toner fusing temperature2 is reduced by up to 35°C compared to conventional EA toner, reducing power consumption during fusing.

This contributes to a decarbonized society.

We are expanding the reuse rate of parts by using a usage history information system to match approximately 30 types of usage history information from the approximately 200 types of usage history information recorded on MFPs with a database of parts life expectancy to automatically diagnose the remaining life expectancy of each part and determine whether it can be reused.

In 1998, we began utilizing recycled plastic from collected in-house products as raw materials.

We sort, crush, and wash the ABS plastic parts of the outer covers and paper trays of used products, and use these as raw materials to introduce them into our own products as recycled plastic equivalent to newly manufactured ABS plastic.

This recycled plastic is guaranteed to be of the same quality as newly manufactured ABS resin, and has acquired UL (Underwriter's Laboratories) certification, a U.S. safety testing organization.

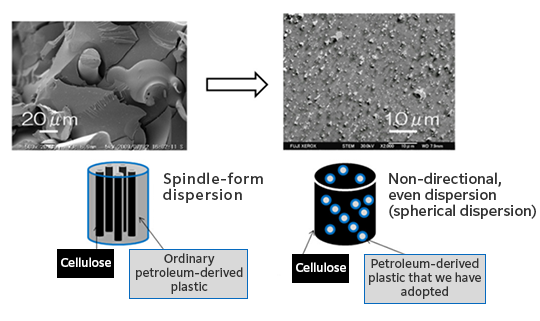

To reduce the use of petroleum-based plastics, we are conducting research and development of plant-derived biobased plastics. Conventional wood-based biobased plastics have had difficulty in achieving high flame retardancy and dimensional stability. We have solved this problem by thoroughly screening flame retardants that have high affinity with cellulose and dispersing them uniformly and isotropically using our proprietary cellulose/ABS alloy technology, and are using them as interior materials for products.

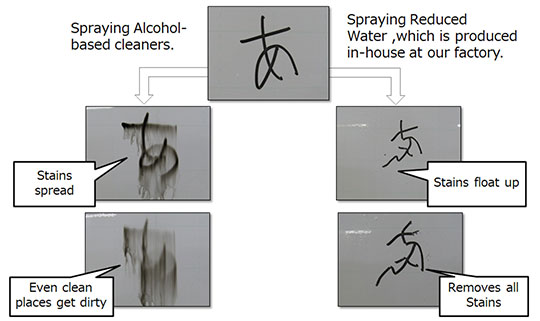

When reusing parts removed from collected used products, we clean them using reduced water that has high cleaning power against oil and grease stains, which is produced in-house at our factory.

Exterior plastics that could not be reused due to yellowing over time have been successfully removed from yellowing by introducing blast cleaning technology, allowing them to be recycled as reusable parts.

Blast processing technology is generally used for deburring to shave the surface of plastics and for the production of frosted glass, but it was extremely difficult to find a suitable abrasive that would not damage the exterior cover but was strong enough to remove the yellowing.

Finding the appropriate abrasive has enabled us to successfully utilize the blasting process technology to remove yellowing from exterior covers, contributing to an increase in the reuse rate of exterior covers.

By introducing the technology into the production process starting in June 2023, the reuse rate of the exterior cover parts could be increased from about 50% before the technology was introduced to around 80%.

We have been developing packaging design technology by utilizing simulation technology to create the packaging quality required for logistics testing even before the prototype is completed.

Recently, we have been working to reduce the amount of packaging used, contributing to the promotion of resource circulation.

Data collected for each product in the production process is usually checked after the occurrence of defects in the market or at the time of shipment. FUJIFILM Business Innovation is working to reduce the number of defective products and waste by setting data on the conditions for producing good products in advance, such as target values and skills, and preventing the line from operating under conditions other than those set in advance.

In order to promote the effective use of resources used in our business activities, we are appropriately managing waste at offices (non-production sites) as well as at production sites. At domestic office sites, we have computerized manifests (industrial waste management forms) and are improving the level of legal compliance management of industrial waste. We have confirmed that our overseas offices manage waste in accordance with the laws and infrastructures of each country, and will continue to do so based on compliance.

Ebina Plant used to generate approximately 20 tons of food waste annually, and in August 2022, all of it was converted to compost for recycling.

We would be most pleased if you would let us know any feedbacks or inquiries you might have about our sustainability initiatives.