National testing laboratory engineer from ASEAN member countries participated in an EMC internship to acquire knowledge and skills in EMC evaluation based on international standards.

The EMC Internship was held from Tuesday, October 21 to Thursday, October 30, 2025, at the International Certification Center, Quality Assurance Department, FUJIFILM Business Innovation Corp. This internship was conducted as part of the “Trainer’s Capacity Building Program for Safety, EMC & Energy Efficiency Conformity Assessment of Multimedia Equipment” implemented by the Japan Business Machine and Information System Industries Association (JBMIA) with support from the Japan-ASEAN Integration Fund (JAIF).

When marketing multimedia equipment such as personal computers, multifunction printers and televisions, conformity assessment tests are required to verify whether these products can be used safely. Association of Southeast Asian Nations (ASEAN) member countries aim for smooth entry into overseas markets and are working to conduct these conformity assessment tests based on international standards at their respective national testing laboratories. However, many national testing laboratories lack sufficient experience in conducting conformity assessment tests aligned with international standards. This results not only in inadequate assessments but also insufficient development of the technical personnel responsible for conducting them. Therefore, to enable ASEAN member states to accurately conduct conformity assessment tests based on international standards within their own countries, JBMIA has been continuously organizing workshops and training sessions since July 2024, based on requests from ASEAN member states, with the aim of developing outstanding technical leaders.

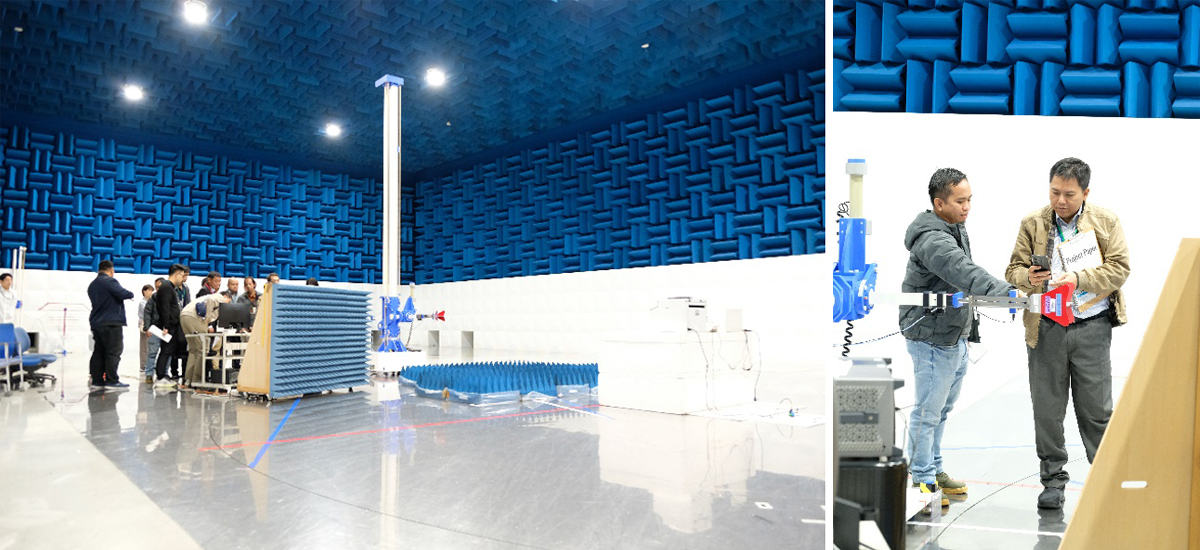

The theme of this internship is “Electromagnetic Compatibility (EMC) Evaluation.” All electrical and electronic equipment, including multimedia equipment, inherently generate weak electromagnetic waves due to their functionality. EMC evaluation tests verify whether these electromagnetic waves interfere with the operation of surrounding devices or, conversely, whether electromagnetic waves from other devices impair the functionality of the product. Conducting these EMC tests is extremely challenging due to the complex requirements for measurement environments and equipment. Furthermore, “calibration” to verify that the measurement instruments used for evaluation are functioning correctly is indispensable. For these reasons, the International Certification Center of FUJIFILM Business Innovation Corp., a JBMIA member, was selected as the venue for this internship. This center holds international calibration accreditation and conducts high-quality testing based on international standards using well-equipped facilities.

Opening ceremony filled with a warm welcoming and high expectations

On October 21, the first day of the internship, an opening ceremony was held to welcome the 12 participants. Addressing the engineers responsible for conformity assessment at national testing laboratories in Indonesia, Malaysia, the Philippines, Thailand and Vietnam, Naohisa Fujita, Corporate Vice President, FUJIFILM Business Innovation Corp., stated, “We sincerely welcome all participants from ASEAN countries to the EMC Internship.” He also explained the center’s features, stating, “This International Certification Center is an accredited testing laboratory based on the international standard ISO/IEC 17025. In the EMC field, we have also obtained ISO/IEC 17025 calibration accreditation, enabling us to deliver highly reliable conformity assessments.”

Eight-day internship explaining complex EMC evaluations from multiple angles across 12 themes

Each lecture featured not only staff from the International Certification Center but also engineers from leading JBMIA member companies in Japan as instructors. A wide range of topics were covered across 12 themes, combining classroom instruction with hands-on training.

The session on “Site Voltage Standing Wave Ratio (SVSWR) measurement,” a method used to evaluate whether an anechoic chamber for EMC testing can properly assess products, provided detailed explanations of the measurement procedure and key considerations. Internship participants listened attentively, taking notes on the SVSWR measurement a technique they had never used in their home countries. They also gained deeper understanding through hands-on experience with the latest measurement equipment.

In the lecture on “Evaluating Multimedia Equipment with Wireless Functions,” participants learned key measurement points through classroom instruction. This included the placement of necessary equipment such as antennas and electromagnetic absorbers for measuring electromagnetic waves, precautions when installing the Equipment Under Test (EUT), and methods to avoid interference between the wireless functions installed in the EUT and other devices. During the practical session using test equipment in a semi-anechoic chamber that replicated the actual measurement environment, participants raised numerous questions.

Furthermore, various lectures were held covering complex EMC evaluation testing from multiple angles—ranging from measurement methods for “Uniform Field Area (UFA)” and “Normalized Site Attenuation (NSA),” needed to determine whether test facilities provide an appropriate measurement environment, to points of caution when testing multifunction printers. Participants shared feedback such as, “I gained essential knowledge for improving the evaluation accuracy at my testing organization,” and “Japan was an early adopter of EMC evaluation testing. Learning in detail about diverse topics over eight days from Japan's experienced instructors was a valuable experience.” They also expressed high expectations for future workshops and study sessions continuing through June 2026.

FUJIFILM Business Innovation Corp. will continue to contribute to enhancing technical capabilities in the ASEAN member state through its active support for the “Trainer's Capacity Building Program for Safety, EMC & Energy Efficiency Conformity Assessment of Multimedia Equipment.”