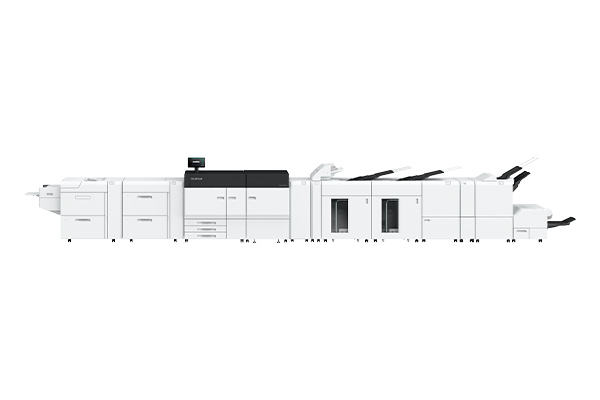

Revoria Press PC2120 supports your business with its consistent high-definition expression built on a proven platform of reliable technologies that won’t let you down. Real-time corrections for colour variations and registration misalignments further maintains exceptional quality and stability even through extended continuous use.

The Smart Monitoring Gate D1*1 monitors changes in colour density and front-to-back registration of print jobs as they are being printed. By scanning print jobs, the system detects and automatically corrects colour variations and registration misalignments in real time, allowing stable print quality even for large-volume jobs. Print optimisation is done without reducing productivity, achieving both high quality and high productivity.

- *1 Optional

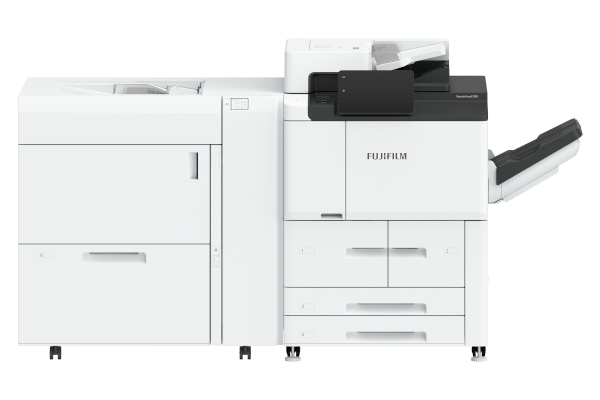

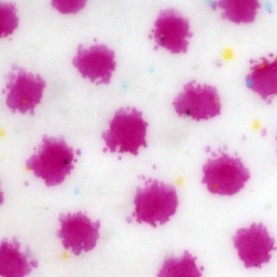

Super EA-Eco toner*2 has one of the smallest toner particle sizes in the world, delivering superior print quality. Gradations and midtones are rendered beautifully and smoothly, while small characters and thin lines are reproduced sharply and clearly.

- *2 CMYK

▲ Offset Printing

▲ Super EA-Eco Toner

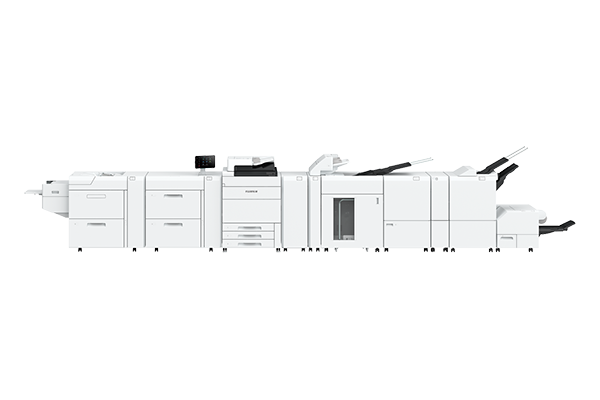

With high-speed, high-resolution RIP processing, Revoria Flow maximises printer productivity. Its advanced image quality features, including gradation, text, and thin line correction, deliver superior print quality. Additionally, high-precision 3D calibration and feedback functions ensure consistent colour reproduction.

Sensors detect the paper position and precisely control rollers, ensuring accurate feeding even during 120 ppm high-speed printing. Stable paper transport can be maintained regardless of media type.

The fuser applies optimal heat depending on the media, achieving high-quality print results across a wide range of papers—from thin to thick paper and banner sheet. Even in 6-colour printing, high-speed printing and superior image quality are maintained without compromising speed.

Curling and sticking between sheets can be prevented by rapidly cooling the paper after toner fixation. This allows subsequent processes to proceed without delay, enabling smooth workflow towards shipment.

Built-in inline sensors automatically perform various adjustments to maintain high print quality.

- Alignment correction

- Transfer output adjustment

- Density correction

The Air Suction Feeder enhances the feed performance of papers, including those with heavy dust, textured surfaces, and coated finishes. The shuttle head transport lifts the paper and separates sheets that would normally be prone to sticking, enabling stable and high-speed feeding.

- *3 Optional

Static Eliminator D1*4 provides a remarkable static elimination effect on a wide range of media, including single-layer film, synthetic paper, water-resistant paper, and tack paper. This supresses paper sticking and significantly improves the efficiency of downstream processes.

- *4 Optional

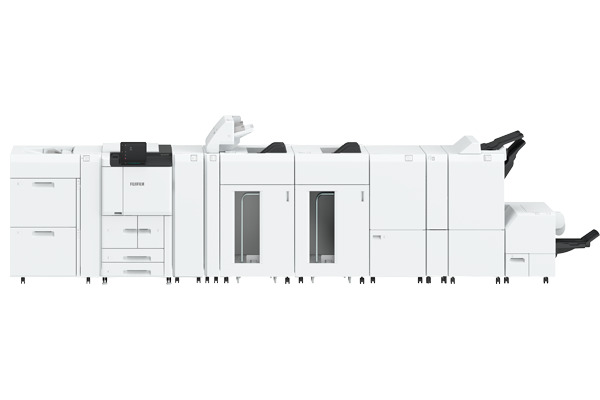

Remote Services enhance machine reliability, uptime, and productivity, thereby ensuring seamless business operations. This service connects our support systems and skilled teams worldwide, providing prompt and precise assistance exactly when needed. This proactive approach, grounded in extensive expertise and comprehensive product knowledge, enables us to deliver the solutions you require.