At Fujifilm Group’s offices and affiliates, we make concerted efforts toward environmental considerations on production sites.

Fujifilm Group is working to reduce emissions of substances that are subject to notification under the PRTR Law (Law Concerning Reporting, etc. of Releases to the Environment of Specific Chemical Substances and Promoting Improvements in Their Management) and substances that are subject to voluntary management.

In order to prevent new contamination, new plumbing and tanks will be placed above ground to make checking for and discovering leaks easier, and existing plumbing and tanks will be moved about ground, redundancy will be scheduled and updates will occur on a stable basis.

Independent environmental survey will be performed for Soil/underground water contamination. For substances used at production sites that fall within environmental standard values, use, storage and wastewater will be strictly managed, underground water quality will be monitored periodically, and in the off chance something is discovered, it will be managed to allow for quick purification.

Please refer to “Result of Independent Surveys Focused on Production Sites” below to view the survey results.

Plumbing and tank surfacing

Soil purification process

Underground water monitoring

| Workplace Name | Survey Completed | Existence of Pollution | Substance Type | Purification Method | Purification Status | |

|---|---|---|---|---|---|---|

| Fujifilm | Kanagawa factory (Ashigara site) |

November 2001 | Yes (Soil) |

Heavy metal type | Soil replacement | March 2002 completed |

| Kanagawa factory (Odawara site) |

June 2001 | Yes (Soil) |

Heavy metal type | Soil replacement | January 2002 completed | |

| Fujinomiya factory | March 2001 | None | ||||

| Yoshida-Minami factory | March 2001 | None | ||||

| Miyanodai district | March 2001 | None | ||||

| Asaka district | December 2001 | None | ||||

| Omiya district | April 2001 | Yes (underground water) |

VOC | Water pump processing | Purification underway | |

| November 2017 (Factory east side) |

Yes (Soil) |

Heavy metal type | Soil replacement | July 2020 completed | ||

| FUJIFILM Optics Co., Ltd. | Sano factory | November 1997 | None | |||

| Mito factory | September 1999 | None | ||||

| Taiwa factory | October 2001 | None | ||||

| FUJIFILM Techno Products Co., Ltd. now:FUJIFILM Healthcare Manufacturing Corporation |

Minamiashigara site | April 2002 | None | |||

| Hanamaki site | June 2001 | None | ||||

|

FUJIFILM Digital Techno Co., Ltd. now:FUJIFILM Optics Co.,Ltd. |

October 2001 | None | ||||

| FUJIFILM Electronic Materials Co., Ltd. | Shizuoka factory | November 2001 | None | |||

|

FUJIFILM Imaging Solutions Co., Ltd. now:FUJIFILM Imaging Protec Co.,Ltd. |

Osaka office | November 2001 | Yes (Soil) |

Heavy metal type | Soil | April 2003 completed |

| Other offices (nine in total) |

June 2001 | None | ||||

|

FUJIFILM Wako Pure Chemical Corporation now:FUJIFILM Wako Chemical Corporation |

Hirono factory | November 2005 | None | |||

- Groundwater will be pumped up from the 11 pumping wells on the grounds of the Fujifilm Omiya Office and purified with two pieces of purification equipment. At the same time, we are making plans on the grounds for diffusion prevention. Up to now, 1038.3kg of substances in question have been recovered. (As of November 2025)

- Ground water is regularly analyzed using observation wells on the grounds to check on the progress of purification, while monitoring is maintained to prevent land subsidence or wells going dry in the area.

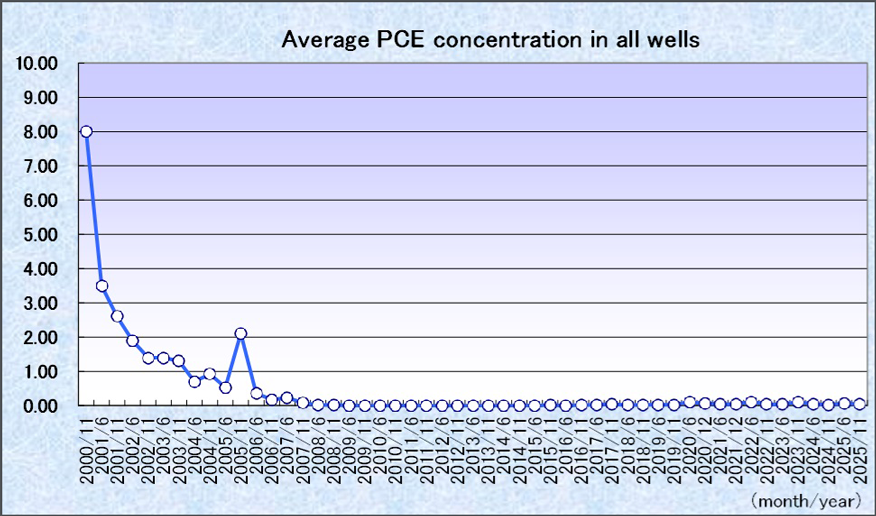

- Results of the aforementioned measures showed an average tetrachloroethylene concentration value of 0.0428mg/L in all grounds observation wells (As of November 2025), to the environmental standard value of 0.01 mg/L.

- Pumping measures and biological purification measures will continue onward, striving for purification and diffusion prevention.

- * Graph of PCE concentration transition due to biological purification measures. Low value maintained through biological purification measures.

In November 2025, surveys went underway regarding well water of homes near the Fujifilm Omiya office. The results of been collected here to be reported. Furthermore, individual examination results were sent separately to the homes in which they were undertaken.

- Water was sampled on November from the 7th to 10th, within the scope designated by Saitama city (Family wells within 200 meters south or southeast of our company in Uetake city district 1, Higashioonari city district 1, and Bonsai city, as well as emergency wells in Junou city district 1).

- We have completed the survey of 63 wells targeted.

- Well water was analyzed for three substances (trichloroethylene, tetrachloroethylene, arsenic).

- Survey results are as displayed in the table below. No wells exceeded the environmental standard values for trichloroethylene, tetrachloroethylene, or arsenic.

| No. | Wells investigated | Wells detected | Standards exceeded | Detected concentration range (mg/L) | Environmental standard value (mg/L) |

|---|---|---|---|---|---|

| Within standards | |||||

| Tetrachloroethylene | 63 | 9 | 0 | - | Under 0.01 |

| 9 | 0.001~0.004 | ||||

| Trichloroethylene | 63 | 3 | 0 | - | Under 0.01 |

| 3 | 0.002~0.009 | ||||

| Arsenic | 63 | 3 | 0 | - | Under 0.01 |

| 3 | 0.002 |

- No major changes were found from previous survey results. We will continue with purification work in the grounds of the Fujifilm Oomiya office and investigate well water.

Fujifilm Omiya Office

Toll-free:0120-38-6655

In light of the strengthening of regulations, we have conducted a survey of the amount of asbestos used in the buildings, facilities and equipment at each of Fujifilm's business sites, and are implementing the necessary countermeasures.

We will continue to implement self-management from the perspective of environmental consideration, and implement measures coordinated with governance.

- Buildings (factories, offices, employee dormitories, gymnasiums, etc.) have been surveyed in accordance with the standards, and places requiring measures implemented and completed.

- Each manufacturing equipment and experiment equipment (Laboratories, Technology, Quality Assurance Departments) implemented usage fact-finding surveys. Safety administration has been implemented for corresponding equipment or parts, and safety is maintained during equipment/parts exchange and disposal through work structures abiding to management procedures. Some manufacturing equipment use heat insulating material or sealant containing asbestos, but have been continuously replacing asbestos products with non-asbestos products after taking measures to prevent scattering.