FUJIFILM Dimatix is a leading supplier of piezo drop-on-demand inkjet products. A focus on innovative performance, productivity, and reliability that is bolstered by rigorous technical support are FUJIFILM Dimatix hallmarks. The company supplies equipment manufacturers with printheads and related services in diverse markets worldwide. Through a commitment to quality, sustainability, customer satisfaction, and its employees, FUJIFILM Dimatix gives the digital printing industry more reasons to smile.

FUJIFILM Dimatix piezoelectric drop-on-demand inkjet printheads are designed for performance, productivity, and durability. They are able to sustainably jet fluids at high frequencies while maintaining their high drop placement accuracy. This precision at full production speed allows every jet on the printhead to operate at high throughput rates.

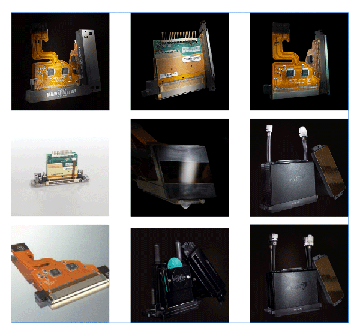

Modular printhead designs can be stitched or bricked when incorporated into the user’s printbar design.

FUJIFILM Dimatix offers a wide range of printheads for different applications.

The actuator components of FUJIFILM Dimatix's bulk piezo actuator printheads are fabricated from monolithic bulk piezoelectric material that is incorporated into jetting modules.

In a jetting module, each jet can be actuated discretely resulting in inherently low cross-talk between jets enabling high productivity.

A specially designed membrane between the pumping chambers and the piezoelectric actuators provides multiple functions. In combination with discretely actuated jets, the membrane results in durable pumping elements with long life and high reliability. This same membrane also isolates the piezoelectric actuators from the fluid path, which serves as protection from aggressive or conductive inks, enabling compatibility with a diverse range of fluids.

Some products also use dual path recirculation to allow the use of inks that settle, such as in the ceramics industry.

These industrial printheads are designed with robust materials for ruggedness and longevity when used with a range of fluid types. The repairability also leads to a lower total cost of ownership.

- 400/600 dpi native resolutions

- Drop sizes ranging from 8-200 pL

- 2-bit greyscale capable

- High-speed printing with optimal fluid laydown

- Durable construction for long printhead life

- REDIJET® ink recirculation for optimal uptime

- Includes fully repairable printhead products

Fujifilm's Si-MEMS technology uses Micro-Electro-Mechanical Systems (MEMS) fabrication techniques to develop printhead families that can take advantage of high-fidelity features. These silicon MEMS-based printhead products contain a precisely controlled nozzle shape and position enabling high drop placement accuracy over high throw distances.

Additionally, FUJIFILM Dimatix printheads include energy dissipating technology, and a range of internal and external coatings yielding wide ink type latitude and reliable quality output.

High-speed jet design paired with Fujifilm’s REDIJET® dual recirculation and energy dissipating technology means quick start-up, fast printing, and reliable jetting. VersaDrop technology provides optimal drop size selection at all times.

The robust silicon structure lends itself to solid, reliable operation and long service life – all of which are desirable attributes for building new printer architectures and enabling new applications.

FUJIFILM Dimatix’s silicon MEMS printheads are made using Fujifilm's proprietary sputtered piezo material, which has a number of advantages. This piezo is poled as it is deposited, which keeps internal stresses low for a long life, and allows for thicker, stiffer films, which contributes to the robustness of the jets.

Also, since sputtered PZT is highly heat resistant, it can survive high temperature manufacturing including the addition of protective coatings that must be applied at high temperature. Since the PZT is not formed from compression and sintering as in bulk PZT, it is less susceptible to the formation of voids, which can concentrate stress. This enables sputtered PZT to tolerate high drive voltages.

FUJIFILM Dimatix’s silicon MEMS printheads provide:

- Up to 1200 DPI

- Drops as small as 2 pL

- Sputtered PZT technology

- Internal and external coating technologies

S-Class and Q-Class printheads from FUJIFILM Dimatix are suitable for a broad range of graphics and other applications. The low crosstalk and excellent channel-to-channel uniformity of their hybrid construction allows Q-Class printheads to deliver unparalleled jetting straightness at firing frequencies up to 50kHz while supporting both binary and grayscale VersaDrop operation.

Their high chemical resistance and precision enables reliable jetting of UV-curable, organic solvent, and aqueous inks onto a broad range of substrates.