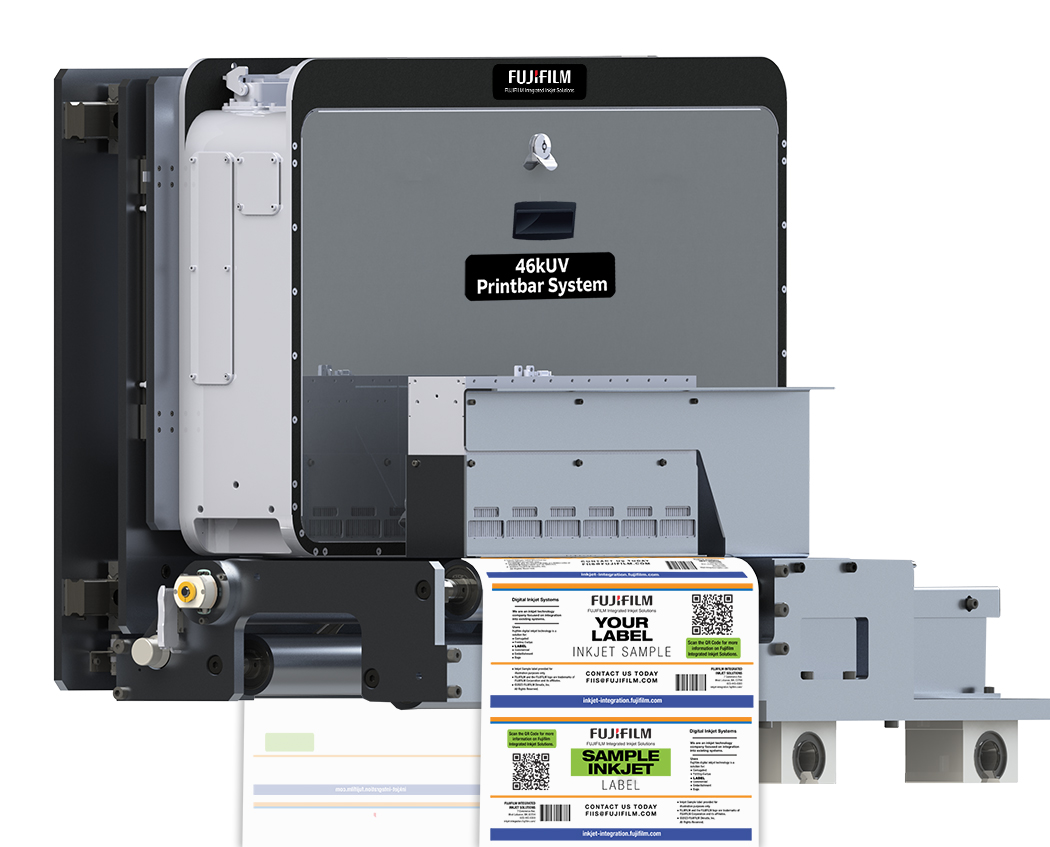

Fujifilm’s print systems are drop-on-demand systems, meaning they use precisely placed inkjet drops to create images up to 1200 dpi. Only the amount of ink needed to create the image is jetted, meaning more precise and efficient printing.

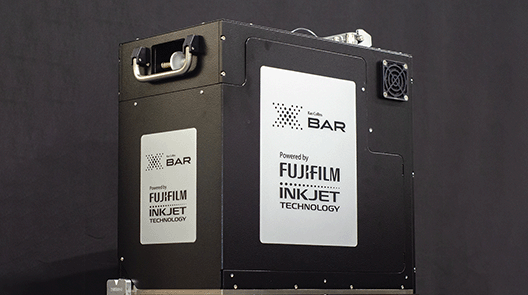

The X-BAR Powered by FUJIFILM Inkjet Technology can reach up to 1200 dpi, making it a high-quality option for single-pass, inline print production.

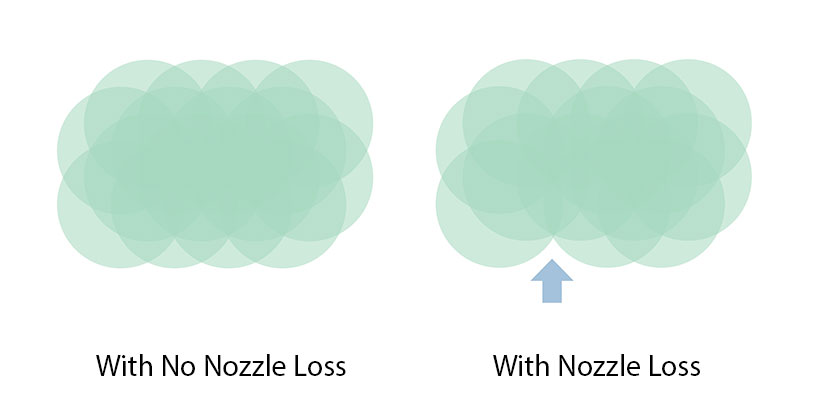

Using the FUJIFILM SAMBA® printhead, the X-BAR can produce fonts as small as 2 points for the most demanding applications. The silicone MEMS design has 32 rows of nozzles, which provide robust image quality capable of producing bitmap or gray scale images at production speeds. The system is also capable of image compensation to ensure image quality throughout the print run.

Fujifilm’s commercial imprinting solutions such as the X-BAR deliver print speeds up to 1000 feet per minute (300 meters per minute). They can be configured to meet typical web-fed press widths as well as typical finishing or production line widths.

The X-BAR leverages Fujifilm’s patented REDIJET® ink recirculation system. This system ensures that ink is constantly recirculating down to the nozzle in a closed loop that will not disrupt printing within the system.

The X-BAR Powered by FUJIFILM Inkjet Technology does not require periodic refurbishment, meaning it is operational more frequently. Fujifilm’s print experts optimize each printbar for reliable sustained jetting.

With two widths and a familiar controller interface, print providers can simply swap out legacy continuous inkjet printbars and swap in Fujifilm’s modern drop-on-demand inkjet printbars with minimal operational changes.

With no refurbishment required, the cost of ownership is lower than with some legacy continuous inkjet solutions. No refurbishment also means more up time and may enable fewer spares needed in inventory.

- Automatic image insetting

- Image compensation

- Automatic nozzle maintenance

- Splice avoidance

- Duplex printing

- Media transports

- Various printbar mounts

- Drying options